XRF

Mosley also created the first attempted X-ray

spectrometer but it proved to be inefficient since it used electrons

that were lost through heat for its energy source. The Bragg brothers also developed an x-ray spectrometer with

the use of a slit and collminator but could not solve the efficiently

problem. An XRF spectrometer was developed by Friedman and Birks

in 1948, their device was built with a diffractometer and used a Geiger

counter for detection of the x-rays. This method proved to be

very sensitive for most of the atomic number range. Karl Manne

Georg Siegbahn of Sweden who won the Nobel Prize in 1924 (pictured

right). He used electrons of high energy for excitation and

measured the x-ray wavelengths of the elements. Siegbahn's work

to improve air pumps and x-ray tubes increased the radiation

intensity.He continually increased the accuracy of his measurements

through crystal gratings and spectographs. These studies lead to

the discovery of the x-radiations of elements. The precision of

his instruments and measurements lead to the complete documentation of

the energy and radiation conditions in the electron shells of

atoms. To read a complete history of all his work please visit http://nobelprize.org/nobel_prizes/physics/laureates/1924/siegbahn-bio.html

Mosley also created the first attempted X-ray

spectrometer but it proved to be inefficient since it used electrons

that were lost through heat for its energy source. The Bragg brothers also developed an x-ray spectrometer with

the use of a slit and collminator but could not solve the efficiently

problem. An XRF spectrometer was developed by Friedman and Birks

in 1948, their device was built with a diffractometer and used a Geiger

counter for detection of the x-rays. This method proved to be

very sensitive for most of the atomic number range. Karl Manne

Georg Siegbahn of Sweden who won the Nobel Prize in 1924 (pictured

right). He used electrons of high energy for excitation and

measured the x-ray wavelengths of the elements. Siegbahn's work

to improve air pumps and x-ray tubes increased the radiation

intensity.He continually increased the accuracy of his measurements

through crystal gratings and spectographs. These studies lead to

the discovery of the x-radiations of elements. The precision of

his instruments and measurements lead to the complete documentation of

the energy and radiation conditions in the electron shells of

atoms. To read a complete history of all his work please visit http://nobelprize.org/nobel_prizes/physics/laureates/1924/siegbahn-bio.html X-Ray

Fluorescence is initiated by the bombarding a

material with high energy x-rays or gamma rays and exciting the

electrons of the material. XRF is primarily used for chemical and

elemental analysis and is efficient in identifying metals like

lead. The

term X-ray comes the energy used

to bombard and excite the material and the term fluorescence refers to

the emission of lower energy radiation after higher energy radiation

has been absorbed.

X-Ray

Fluorescence is initiated by the bombarding a

material with high energy x-rays or gamma rays and exciting the

electrons of the material. XRF is primarily used for chemical and

elemental analysis and is efficient in identifying metals like

lead. The

term X-ray comes the energy used

to bombard and excite the material and the term fluorescence refers to

the emission of lower energy radiation after higher energy radiation

has been absorbed.

The X-rays have enough energy to

force the electron to surpass its ionization energy and actually eject

the electron from the atoms in a 'photoelectric effect', the

resulting instability forces other electrons to fall into the gaps and

thus release energy. The energy is released as a photon with a specific energy

relating to the difference in energy of the orbitals. This

emitted radiation is characteristic of the specific atoms present in

the material. The wavelength of the emitted radiation can

be calculated using Plank's Law. The inner K and L shells are most

typically involved, on the x-ray spectrum the peaks are labeled as

K,L,M,N to show the shell where the electron was originally

located.

Images from http://www.amptek.com/xrf.html.

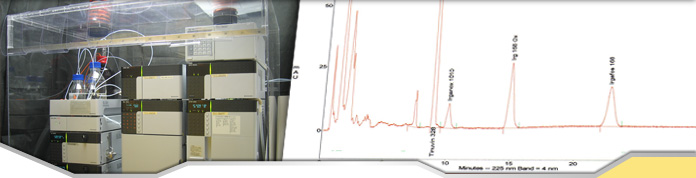

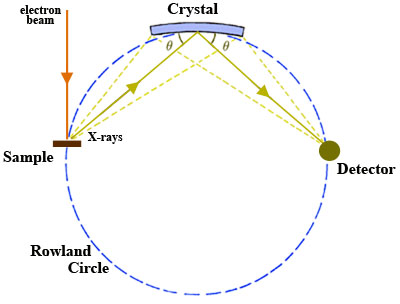

One type of XRF

spectrometer is the wavelength dispersive spectrometers that use a

diffraction crystal to focus the specific wavelengths on to the

detector. The wavelength range is adjusted by changing the angle

of

the x-rays hitting the surface of the crystal. The

x-rays are then passed from the crystal on to the solid surface

detector. The angle of the x-ray, the analytical crystal and

detector must all be contained in precise measurements of each other,

this is referred to as the Rowland Circle. The crystal is

tangent to the circle and the slit for the x-rays and the detector are

points on the circle. The circle is pictured to the left from

http://serc.carleton.edu/research_education/geochemsheets/wds.html.

One other type

of XRF Spectrometer is the Energy Dispersive spectrometer which focuses

all of the emitted x-rays directly onto an energy analyzing

detector. These are not as sensitive as its wavelength dispersive

partner and also have a lower resolution.

Generally the XRF method

is non destructive to the subject being analyzed. The most

accurate readings are achieved when the material is ground down and

formed into a uniform sample, please refer to the Sample Preparation

page for the methods that the toys are prepared for analysis.

This extensive testing protocol is used by industry when toys are

applying for safety ratings so that their products can be marketed in

the United States and abroad. However, the XRF method is very

versatile since it operates with xray that can penetrate most any

substance. The XRF

method can be none destructive to the material and therefore is great

for

use in the field. It is also very efficient and very cost

effective. Agencies use portable XRF scanners that use

gamma rays as the energy source (Pictured to the right) to voluntarily

test toys at community events and health fairs. These XRF

scanners can also be rented rather inexpensively to test not only

children's toys but surface paints, soil, minerals and any other

household application. Accuracy has improved with these devices,

a major concern was the control of how deep the x-rays penetrated the

sample. This is an issue when testing a material for surface

paint since the substrate which may be lead free would influence and

lower the percentage results of the surface contaminants.

Generally the XRF method

is non destructive to the subject being analyzed. The most

accurate readings are achieved when the material is ground down and

formed into a uniform sample, please refer to the Sample Preparation

page for the methods that the toys are prepared for analysis.

This extensive testing protocol is used by industry when toys are

applying for safety ratings so that their products can be marketed in

the United States and abroad. However, the XRF method is very

versatile since it operates with xray that can penetrate most any

substance. The XRF

method can be none destructive to the material and therefore is great

for

use in the field. It is also very efficient and very cost

effective. Agencies use portable XRF scanners that use

gamma rays as the energy source (Pictured to the right) to voluntarily

test toys at community events and health fairs. These XRF

scanners can also be rented rather inexpensively to test not only

children's toys but surface paints, soil, minerals and any other

household application. Accuracy has improved with these devices,

a major concern was the control of how deep the x-rays penetrated the

sample. This is an issue when testing a material for surface

paint since the substrate which may be lead free would influence and

lower the percentage results of the surface contaminants.

| Spectroscopy Home |

Toy Safety Standards |

Sample Preparation |

| XRF |

AAS |

Lesson Plan |