Textiles, Synthetics, and Plastics

Figure 1. Image of several fabrics that have incorporated brightening agents (3).

|

FLUORESCENT

WHITENING

AGENTS

IN LAUNDRY DETERGENT

& PAPER

|

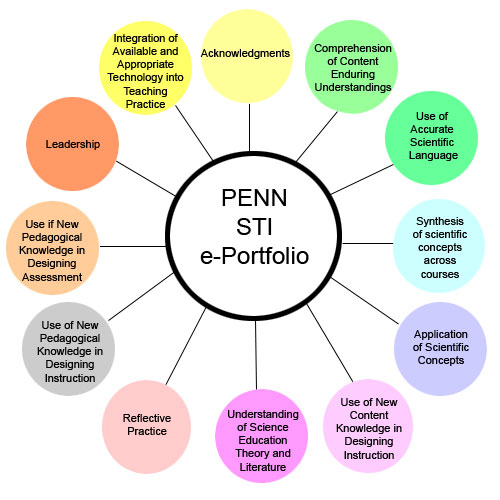

| 1:

History 2:Importance and

Usage 3:

Spectroscopy 4: Current

Studies 5: Future Expts. |

| 6: HS Classroom

Lesson: A: Lesson

Plan B:

Worksheets C: Instructor

Guide |

2.

Importance and Usage

2.

Importance and Usage In 2006, textiles still accounted

for 25% of worldwide fluorescent brightener use (1). Synthetics and plastics

accounted for an additional 5% of total use (1).

In 2006, textiles still accounted

for 25% of worldwide fluorescent brightener use (1). Synthetics and plastics

accounted for an additional 5% of total use (1).| 1.

fluorescent emission in the

desired range (i.e. they give off the correct color) (5,6,7), 2. fastness to washing, perspiration, and sunlight (i.e. they last long because they bond or adhere well to the base material) (5,6,7), and 3. nonhazardous properties (i.e. humans can be safely exposed to them). |

As brightener use in textiles

has increased, US consumption of these brighteners in detergents has

also steadily grown over the years. In 1994, approximately 64.0

million pounds of brighteners were used in detergents, and it was

estimated that US consumption of brighteners, in detergents alone,

would increase 2 to 2.5% per year (2). In 2006, detergents accounted for

the largest and primary use of brighteners--40% of worldwide use (1).

As brightener use in textiles

has increased, US consumption of these brighteners in detergents has

also steadily grown over the years. In 1994, approximately 64.0

million pounds of brighteners were used in detergents, and it was

estimated that US consumption of brighteners, in detergents alone,

would increase 2 to 2.5% per year (2). In 2006, detergents accounted for

the largest and primary use of brighteners--40% of worldwide use (1). In 2006, FWA use

in paper accounted for 30% of worldwide use (1). FWAs were

first used to whiten paper in Europe; the US also started using FWAs as

a way to cut costs while producing paper that was still pleasantly

white (the base pulp would not need to be bleached as much). (14).

In 2006, FWA use

in paper accounted for 30% of worldwide use (1). FWAs were

first used to whiten paper in Europe; the US also started using FWAs as

a way to cut costs while producing paper that was still pleasantly

white (the base pulp would not need to be bleached as much). (14).

WORKS

CITED:

|